About TWIN

Chris Beuker and Oane Visser about the origins of the TWIN Rocker Machine.

It’s the skater who wants to polish his skates himself, in the hotel or even on the rink. Without the proper equipment or professional experience one probably will eliminate the perfect radius when polishing or the traverse will no longer be perpendicular. For this purpose Oane Visser and I developed the TWIN-sharpening table and the TWIN-radius sharpening machine. In this way the sportsmen will be able to keep their skates in top shape without being dependent upon complicated large machines, expertise and uncontrollable tolerances.

For many decades, Chris Beuker has been active in World Cup skating. He has closely followed all technical developments and personally contributed to many innovations. ‘A skate needs to slide, and at the same time, provide grip for the push off, but it mustn’t dig into the ice.’ This indicates the degree that Chris Beuker observes the importance of the correct sharpening of ice skate blades and the distribution of forces on the ice. ‘The biggest problem during or just before matches isn’t so much the sharpening for which exist efficient machines.

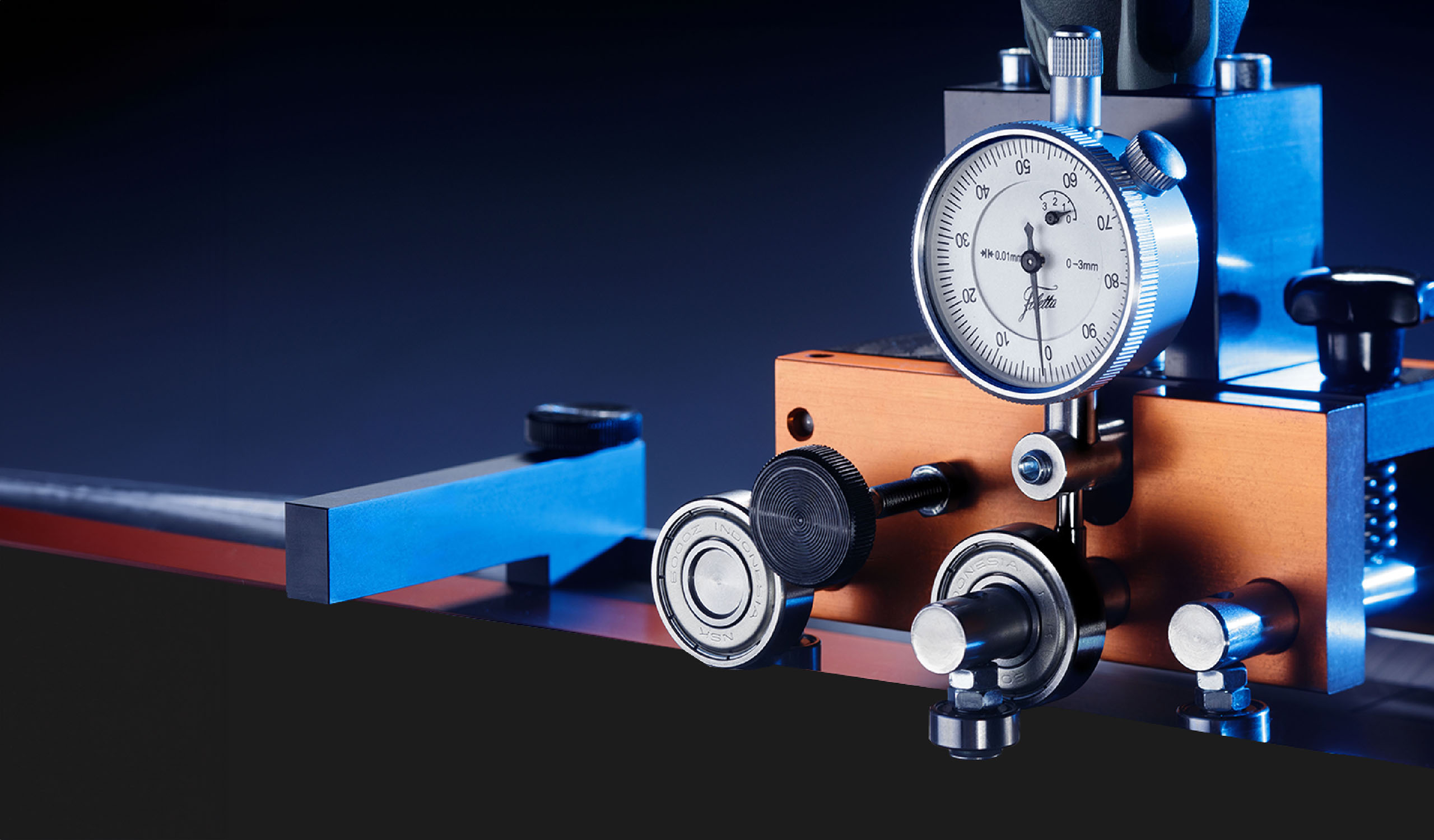

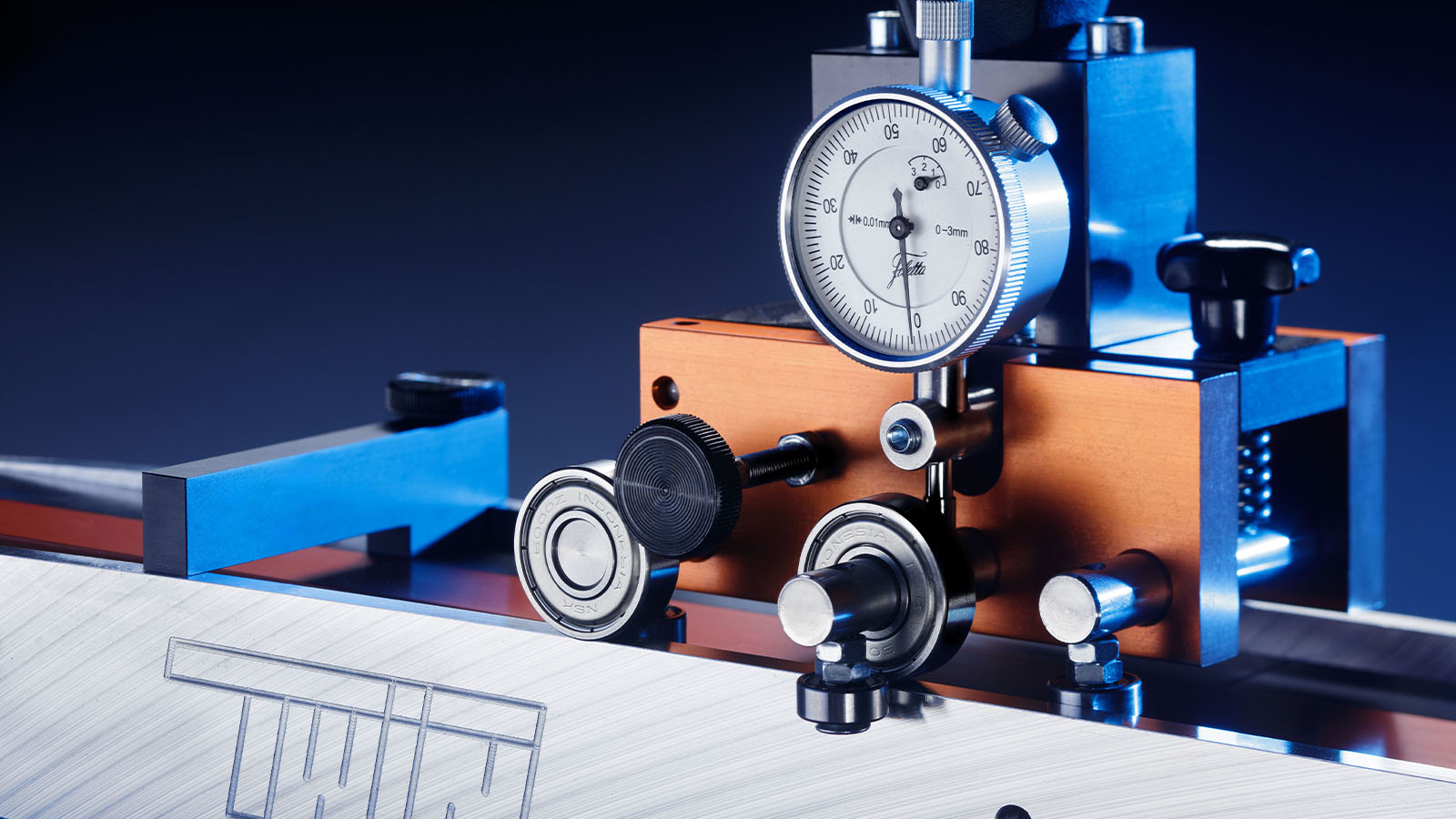

Chris Beuker’s design of the TWIN, together with the knowledge of Mr Oane Visser has been translated into a high-tech precision tool. In engineering the TWIN, great effort has been made to reduce as much as possible the internal tolerances. Thanks to a reduction of the number of components, the application of stainless steel axles with dust-proof bearings and the realisation of a very rigid assembly, the highest possible accuracy has been reached.

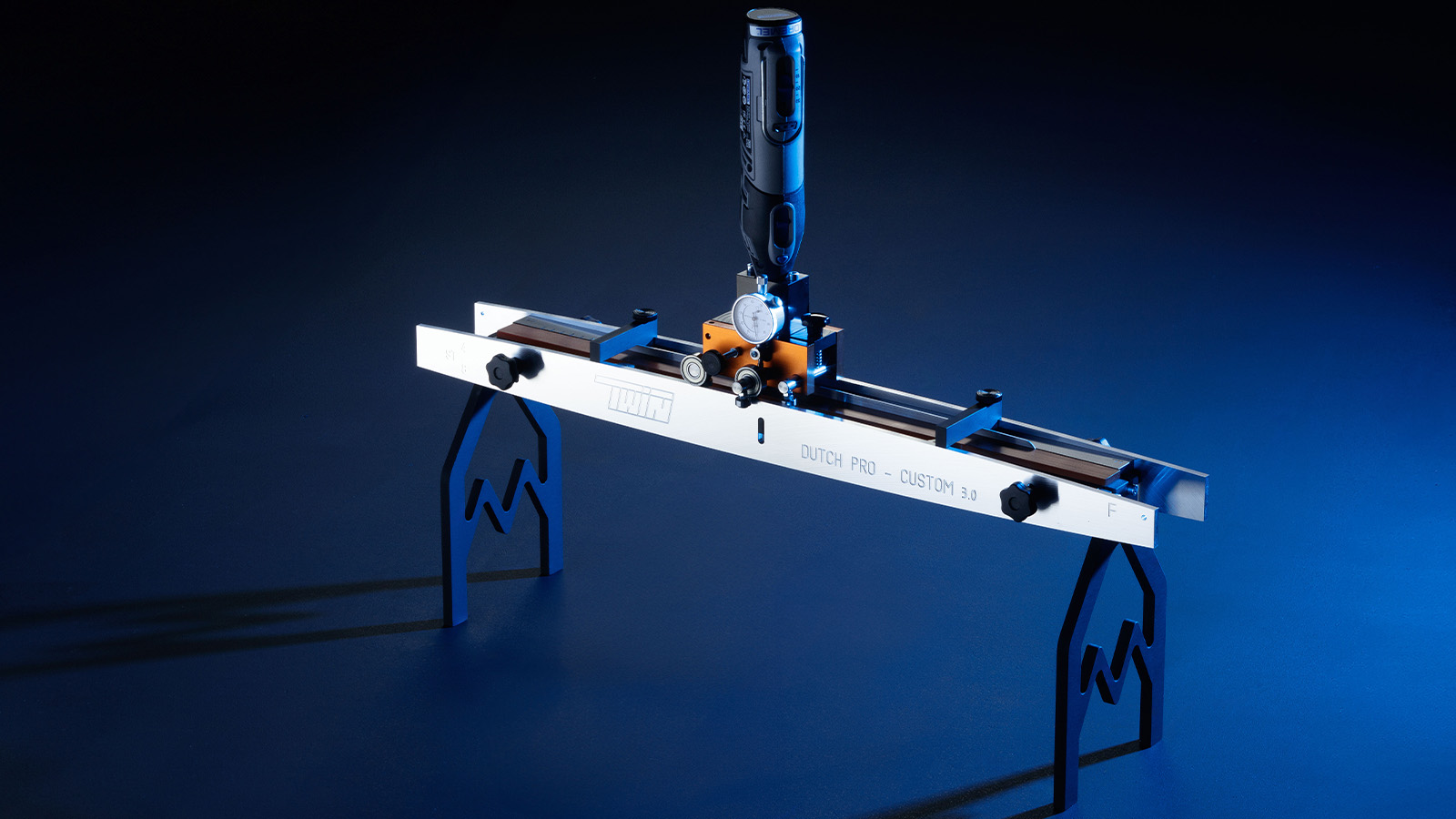

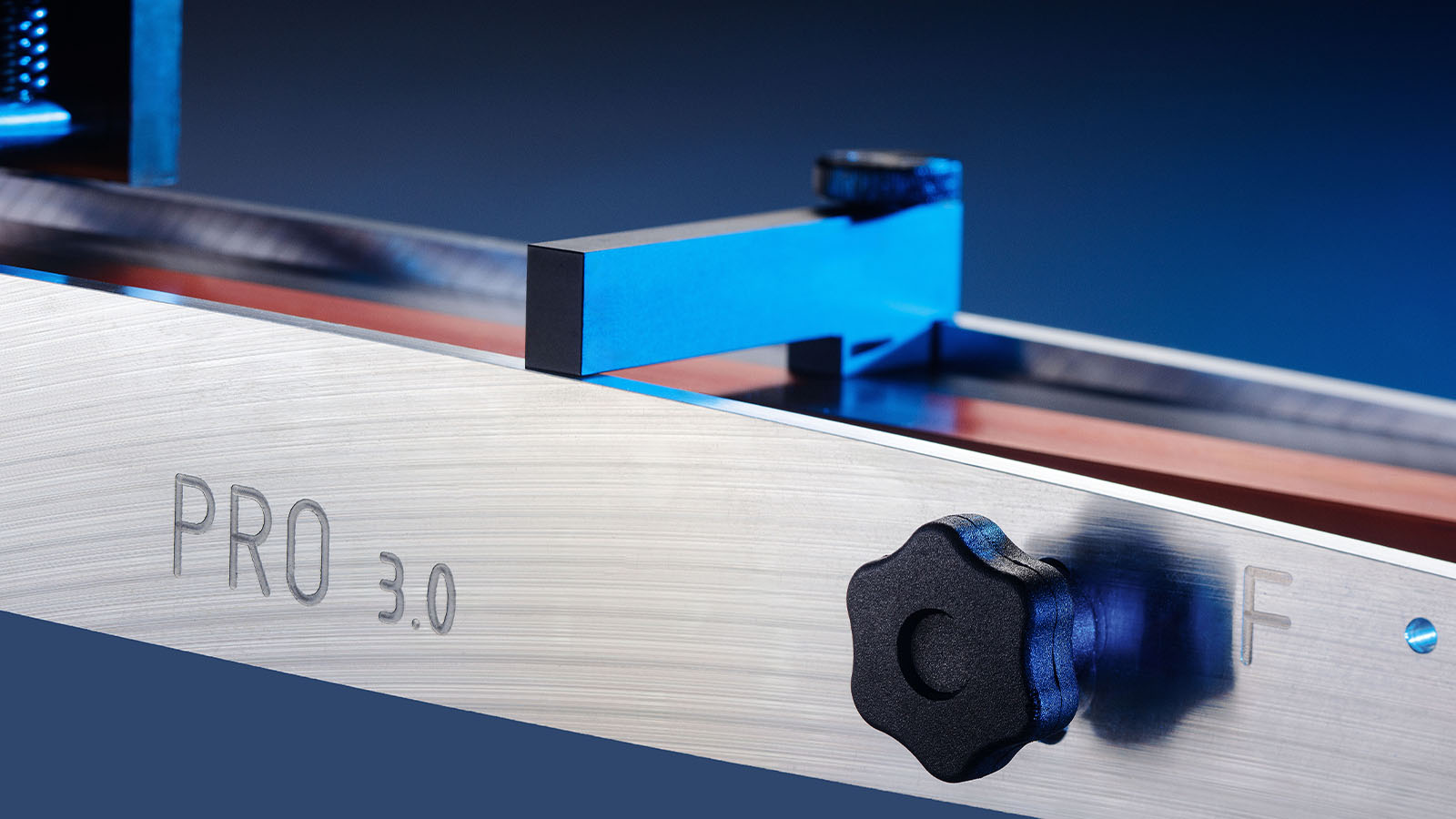

The TWIN Radius Rocker Machine is hand-assembled in small quantities. All components are CNC manufactured. Anodic coating treatment in different combinations has been applied to the aluminium table with extendable supports.

In order to achieve easy usage of the TWIN and, at the same time, accurate sharpening, both the sharpening table and the radius sharpening machine are equipped with some clever features. For the assembly and clamping of the blades two clamps per blade are used, the design of the clamp surface secures a perfectly perpendicular position along the whole length of the blade. The calibration applied enables a precise symmetrical assembly of both blades.

The method of clamping determines the difference between the TWIN Longtrack (LT) and Shorttrack (ST) versions. Except for the precision templates (available in standard radii from 20 to 27 m.) the TWIN-ST isn’t flat, but equipped with the desired curve cut along the clamping surfaces to match the bent blade used in short track speed skating.

The templates are available in standard radii, but a personal radius or a combination of various radii into one template can also be realized. These made-to-measure templates will be defined together with the skater in order to obtain the secret formula for the best performances.

Durable materials, precision engineering, high quality assembly and finishing have been applied during both the development and manufacturing process. The TWIN is a real precision tool, guaranteeing to provide the perfect sharpening of speed skate blades.

Topsport and technique is a logical combination according to Chris Beuker, founder and inventor of the TWIN Rocker Machine. ‘The achievement of the highest performance requires perfect technique,’ says Chris Beuker. ‘To achieve the highest possible level of technique is my personal challenge!’

Chris Beuker | Founder of The TWIN Radius Rocker Machine

features

The TWIN Rocker Machine 3.0 PRO

In order to achieve the best performances, skaters need to rely on their equipment – and nothing is more important than perfectly rockered blades. With the new TWIN Rocker Machine 3.0 it’s easier than ever to keep and maintain your blades in top condition.

Optimal precision

For longtrack & shorttrack

Adjust two skates at once

Improved materials

Anodised finish

Lightweight

The TWIN Rocker Machine 3.0 is the most compact and accurate radius sharpening machine available on the market. Easy to transport and lightweight, it has a super-stable set-up and is usable without electricity anywhere you are. Without the radiusing machine part, the TWIN sharpening table on it’s own offers the perfect jig for sharpening, polishing and deburring with both blades in one set-up for perfect symmetry. The blades can be rockered to any radius desired thanks to the large variety of templates that the TWIN has to offer. If your desired radius template is not available, don’t worry, we can create custom templates specialised for the TWIN to order – just send us your numbers.

The LT version of the TWIN Rocker Machine has been designed and manufactured especially for long track speed skaters. The TWIN-LT sharpening table provides a perfectly perpendicular clamping position of the blade, along the whole length. For skates with “bent” blades, have a look at the TWIN-ST, for shorttrack.

When the sharpening table is used together with the TWIN radius sharpening machine and the templates with desired radius-profile, sharpening, polishing and deburring will be very easy. After the templates have been clamped, the DREMEL® driven sharpening machine with diamond head can easily be positioned on the template guides. Thanks to the adjustment screw, the setting of the grinding height requires little effort. After this the TWIN will do the rest. Move the sharpening machine back and forth using little pressure, thus copying from the template to the blade. The TWIN uses a standard, easily available multitool for powering the cutting head (the DREMEL® is included in the delivery). It is easy to replace and relatively cheap. Through the use of rechargeable batteries, operation will be possible without a local AC power source The DREMEL® is also suitable for mains voltage of 110~230V and 50/60Hz. Regardless of where you are: in Heerenveen, Hamar or Vancouver.

Worldcup teams around the world are relying on the TWIN Rocker Machine 3.0 for both Shorttrack and Longtrack speedskating

Technical specifications

The TWIN Rocker Machine 3.0 PRO is available for longtrack (LT) and shorttrack (ST).

Dimensions: 540 mm length, 200 mm width, 20 mm material thickness.

Weight: 2 kg.

Voltage: 110~230V

Hertz: 50/60Hz

Version: anodized aluminium, black/orange. Folding legs with adjusting bolt for stability, also on unlevel surfaces. Perfect perpendicular clamping of skate via a 2x turning cam/slide and two clamps per blade.

Symmetrical assembly is possible through calibration on each side. Ready for all operations in one assembly!

Accessories included: two templates with one radius at choice (20~27 m.).

TWIN Sharpening Table ST

For Short Track with bend

TWIN Sharpening Table LT

For Long Track without bend

TWIN Sharpening Table MINIMO

Suitable for ST & LT templates and sharpening machine

Dimensions: 110 x 105 x 273 mm. Weight: 4,3 kg excl. accessories. Dremel® multi tool.

TWIN Duo Templates Short Track

TWIN Duo Templates Long Track

The DREMEL® multi-tool, included in the delivery, has its own battery. Choose an extra battery to be on the safe side. Suitable for every mains voltage (110~230VAC, 50/60Hz).

For the manual control during the polishing and deburring the separately available micrometer is an essential instrument. Available in synthetic material, black colour.

Except for the allen key(s), that are included in the delivery, we can supply a complete toolset. This toolset consists of: screwdriver, combination pliers and socket wrenches of various sizes.

Flight case with compartments and soft padding. Also available for the TWIN MINIMO.

Get a personal offer or more information

Instruction video

HOW TO USE THE TWIN ROCKER MACHINE 3.0 PRO

FAQ

Frequently asked questions

The multipurpose setup of the TWIN Rocker machine ensures that you can get your skates ready for maximum performance with one single machine. The TWIN Rocker machine serves the following purposes:

- Rockering

- Deburring

- Sharpening

- Polishing

The TWIN Rocker machine was initially developed for long track skaters, but is now also available in models that are suitable for short track skaters. You can now provide optimal conditions for both long track and short track skates with the TWIN Rocker machine.

Basically nothing, except a little working space! The wireless DREMEL® ensures you can always operate your TWIN Rocker machine, even without any electrical outlets nearby. The foldable, adjustable legs provide the required stability, even on unlevel surfaces.

Sure you can! It’s lightweight and fits easily in your luggage. We can even deliver your TWIN Rocker machine with a customized flight case. Give your skates a final touch in your hotel or right next to the ice rink: the TWIN Rocker machine does it all.